Guest Post: The Five C’s of Integrity Management

This is a guest contribution from Wayne Bryce, President & CEO of JANA Corporation, based in Aurora, Ontario, Canada.

Many industries, when first confronted with the challenge of modeling risk, started with the use of index or ‘scoring’ type risk models. While the limitations of these models are evident and widely documented, they still persist because of a common misconception that alternative approaches, such as quantitative risk modeling, are complex or require more data than is currently available.

JANA has been providing risk modeling and integrity management consulting services to utilities in North America for nearly two decades. We’ve developed a very specific, quantitative approach to anticipating risk. In a nutshell, we look at the potential failure mechanism of your pipeline, and once we know how it will fail, we can express it mathematically in a reliability equation. Then we use real data that you already have about your pipeline and its historical performance, and apply it to the equation to create a statistical model that can reliably predict the future.

We’ve helped both natural gas transmission and distribution pipeline operators transition from an index-based to a quantitative risk model-based approach—and we’ve learned some key lessons along the way. We recently formed a partnership with Copperleaf to create the Copperleaf Integrity Management (CIM) solution, a fully integrated software solution that combines JANA’s risk models with Copperleaf’s risk-based decision methodologies. CIM is designed to help organizations create comprehensive, defensible and prioritized integrity management plans and avoid exposure to unacceptable levels of risk.

I’d like to share some recommendations for a successful implementation of a quantitative risk modeling approach to managing pipeline system integrity. These key lessons can be distilled into the five C’s of integrity management:

1. Correct

Data is a critical component of any risk modeling approach and integrity management program. Not all data, however, has equal value in assessing risk. My first recommendation is to start with the data you have. There is no such thing as “perfect” data; any amount of data is useful! Quantitative risk models can be implemented based on a minimum level of initial data collection, and can later be used to show the value of certain data and allow disposal of other data that does not provide value.

However, even if “perfect” data is available, it still needs to be processed correctly or you’ll end up with wrong results. Certain inherent rules need to be followed, and those rules need to be applied consistently, no matter what, to ensure the risk models will produce correct and accurate results.

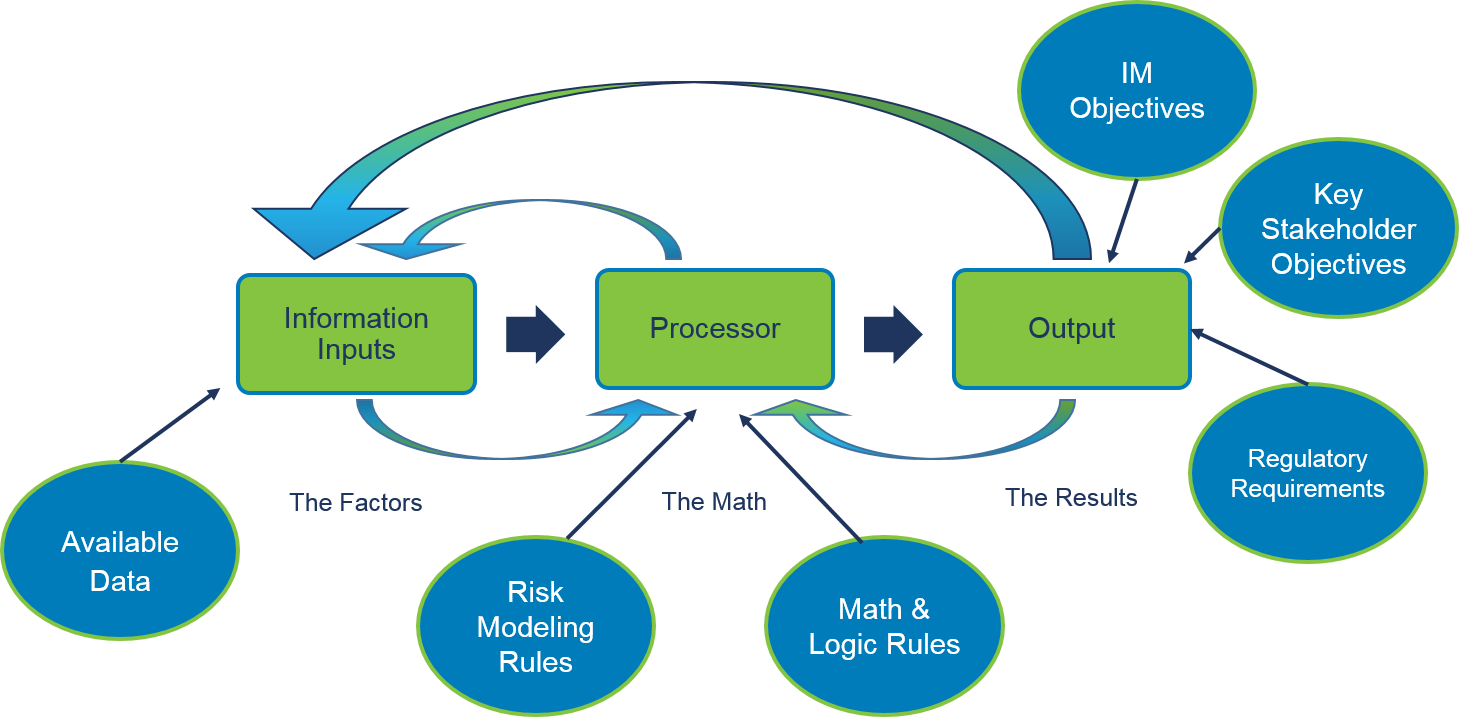

JANA’s risk models are composed of three components: model inputs (factors or data), processor (where data is manipulated), and model outputs. But we don’t start there. As illustrated in the diagram below, the objectives of the integrity management program should ultimately drive the requirements of the risk modeling approach.

2. Credible

As well as being correct, the risk models need to be credible. They need to be accepted by users and stakeholders which requires transparency, complete documentation, validation, etc. At the highest level, the risk models need to:

- Predict what you need predicted

- Be usable, i.e. implemented with currently available data and updated as data, modeling approaches and regulations evolve

- Be as accurate as possible

- Be transparent and defensible through documentation, training and support

3. Configurable

Each utility’s asset base, data and processes are somewhat different, which means an integrity management solution for one organization will not meet the needs of another. Risk models must be easy to implement, and tailored to the unique nature of your assets and available asset data. As data, regulations, and processes evolve, the solution also needs to be easily configurable to adapt to future requirements.

4. Compliant

The integrity management solution also needs to be compliant, to meet constantly evolving regulations and regulatory expectations. The CIM solution for example, is fully compliant with the 49 CFR Part 192 Subpart O Pipeline Safety Regulation and ASME’s B31.8S Managing System Integrity of Gas Pipelines Standard.

5. No Compromise

Lastly, a no compromise solution is needed. Both the risk models and the integrity management software solution need to deliver what is needed for the operator’s integrity management program. The solution also needs to integrate input from your organization’s subject matter experts to ensure all available information on the specific assets and processes are captured.

If you are looking to implement an risk-informed integrity management strategy, please get in touch! In the meantime, feel free to download the Copperleaf Integrity Management brochure to learn more.